Question: When is the best time to laser cut your parts?

Answer: When you have extremely tight tolerances or very thin wall widths.

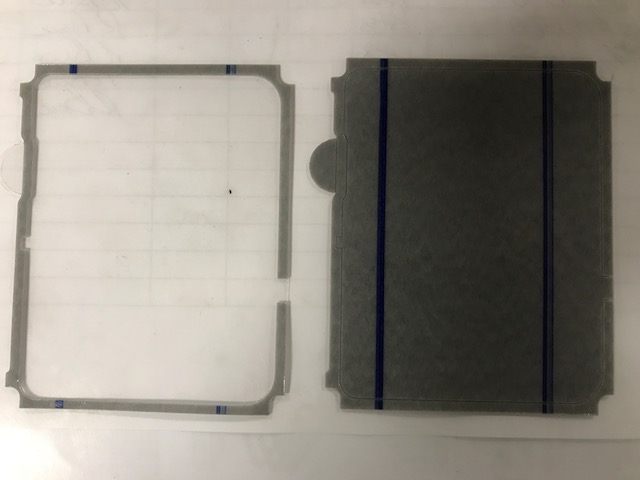

One of our customers needed to fasten a shock absorbency panel to a piece of underground equipment for the construction industry. Through a series of prototype tests, they determined that 3M’s highly adhesive VHB tape would be the best solution for this particular application. Our sales engineer Albert Diedricks explained, “We did send them other materials to test, but the VHB tape was determined to be the best to aid in the construction equipment durability, in providing a permanent seal, and for maximum shock absorbency.”

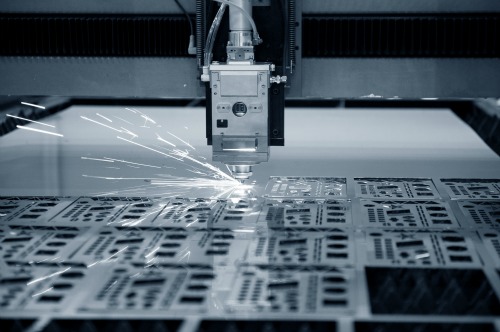

Laser cutting is particularly effective for running smaller parts that have smaller wall widths, including projects that require 1/32 of an inch or 1/16 of an inch. In addition, if you have particularly expensive materials where tighter nesting would be beneficial, laser cutting is a great solution.

Using a punch press is less expensive and the run times can be slightly faster, but if your project requires those smaller wall widths, you cannot build a steel rule die that would be effective. Other gasket manufacturers, who do not have the high tech laser equipment that Gasket Engineering has, might recommend a two-stage die in order to meet the wall width, but that can add cost and time to the project.

With our smart engineers and our state-of-the-art laser cutting equipment, Gasket Engineering was able to provide a cost-effective solution to run those smaller parts with tighter nesting, smaller wall widths and the most exacting cuts possible. Albert Diedricks explained, “We pride ourselves on providing long-term solutions to our customers. This particular customer services the construction industry and has been running this part for close to two years now.”