Crafting Intricate Parts: How Rotary Cutting is Like Seven Layer Dip

Intricate Parts

Although the finished product will not be edible, rotary cutting can stack a variety of “ingredients” and make them as palatable to a manufacturer as the best multi-layer dip is to a party guest.

Typically used for high-speed, high volume projects that require anywhere from two to seven substrates to be joined to form a part, rotary cutting has been part of Gasket Engineering’s offerings since the 1990’s when the company made nearly 60 percent of the US-based intricate parts needed by Motorola.

What’s so great about rotary cutting?

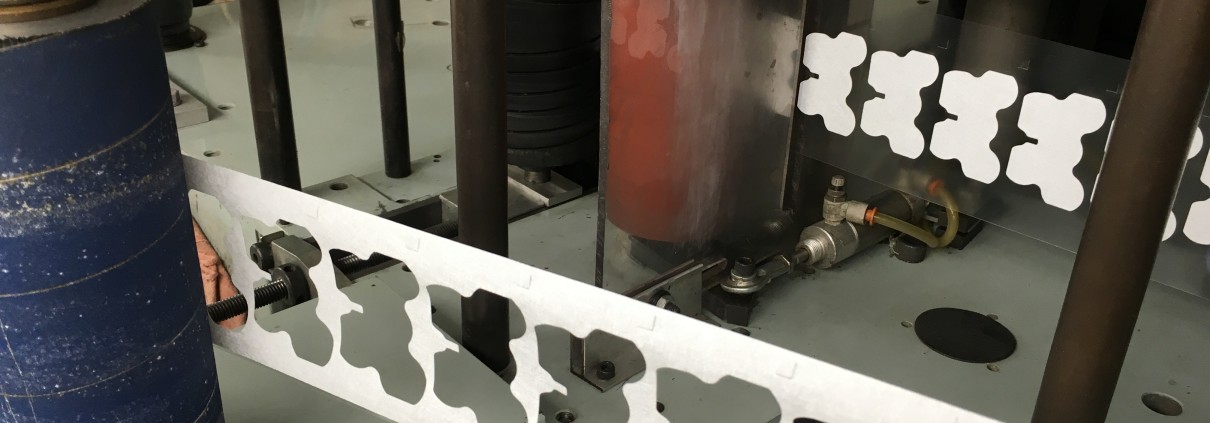

Gasket Engineering’s advanced rotary cutting capabilities have the ability to process multiple substrates in one harmonious pass. This type of process makes a nice, clean homogenous part out of multiple materials.

But it’s much more complicated and intricate than just laminating seven layers together. You can also remove and introduce liners, use different adhesives on different sides of the materials and stack different materials on top of each other.

Clients bring us incredibly complicated and intricate parts that need to be made–ones with voids and adhesives and liners and precision requirements from every industry imaginable. That’s probably why we ask so many questions–because we want to get it right! We know that there are so many elements that need to be considered in properly making an effective part. Our expertise in designing the proper processes is just as important as our knowledge of materials and production methodologies.

Intricate Processes

Sequencing is important.

Our knowledge of the right process design is only secondarily critical to the finished product itself. For example, it would not be uncommon for a customer to request to have a conductive material sandwiched between two insulatory materials and then have another adhesive that is put on a liner. That material could have multiple cuts so that some of the conductive material is exposed while some of it is covered.

For these types of intricate parts, those layers have to be processed at different times and in different ways in order to be properly laminated or delaminated and have the appropriate cut patterns and adhesives laid down. That process needs to pull off scrap at the right time and make multiple cuts in multiple materials.

That’s how we make the intricate parts that are customers bring to us. Our engineer has to be my knowledgeable about the materials themselves and how best to convert them, as well as how to properly process them through one of our machines. It has to be sequenced properly so that it doesn’t negatively impact other layers or aspects of the part production. That’s why we say that the sequence is as important as the material placement.

Our experts also need to be familiar with which machines should be used for different jobs. We run our rotary cutting projects through one of two different types of machines. Our Delta presses are software driven so each station can run at independence speeds, while the Allied presses all run at the same speed. Depending on the types of parts being made and the particular requirements of those intricate parts, our engineers will recommend the right machine for the job.

No matter which machine you use, we have optic registration on all machines for maximum precision.

Have you got ayn intricate parts or tricky problems that you’d like help with? Feel free to give one of our engineers a call at 813-363-8333. If you’d like to read more about our rotary cutting capabilities, download our free ebook about The 10 Most Important Considerations for Rotary Cutting here