What’s the difference between regular cloth-insert rubber (rubber coated fabric)and more expensive “Engineered Coated Fabric” or diaphragm material?

This important question about engineered fabrics needs to be answered in order to know whether you need to invest in more highly-engineered fabric or diaphragm material or whether the more cost-effective rubber coated fabric or silicone coated fabric will work for your particular application.

Cloth insert is a pretty small niche and uses fairly inexpensive cloth layered in between layers of uncured rubber, then cured into a final cohesive cured product. This rubber coated fabric (or silicone coated fabric) is used for simple applications, but if you have a more technically challenging application, like situations where you require barrier materials for chemically aggressive environments, you will probably want to solve that with engineered fabric that has composite design and better material technology.

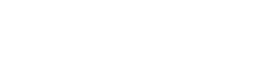

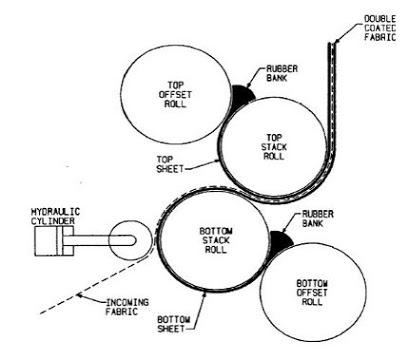

The more expensive diaphragm material or “engineered coated fabric” are different materials than cloth-insert rubber coated fabric or silicone coated fabric. Depending on the thickness, diaphragm material can be made like a cloth-insert material with a layer of a “higher tech” woven fabric like nylon or Nomex added between layers of high grade uncured rubber, then cured. Sometimes a liquid-like uncured rubber is coated onto both sides of the engineered fabric and cured, usually for the thinner materials.

Diaphragm material typically has the tightest thickness tolerance in the rubber industry and have a multitude of other specifications that control the bursting strength, wicking properties and stretch of the material. Engineered fabric usually requires a higher level of investment and is normally used for more precision applications in pressure regulators, valves and flow control devices.

In situations that create higher pressures, a synthetic fabric reinforcement can increase the burst resistance, which can extend product life, reduce deformation, and allow the use of thinner sections to improve sensitivity of control. An example would be in control and metering valves in aircraft fuel systems.

Gasket Engineering is one of only a handful of Trelleborg Master Fabricators in the United States. Trelleborg is a company that sells engineered fabric for many different applications. We have been given this designation because we know who to properly handle and convert the more costly engineered coated fabric or diaphragm material in such a way as to maximize our customer’s investment and deliver highly-engineered gaskets for use in these precise applications.

If you believe you need engineered fabric or diaphragm material for your challenging application, or even if you think you only need a rubber coated fabric or silicone coated fabric, give us a call. We’ll help you determine which option would be best for your situation. We’d love to help!

If you’d like to see the specification sheets for our Trelleborg engineered fabric or diaphragm material, check out the “Diaphragms” tab on our Materials page.