Profitable Part Production: There’s Always More Than One Way to Produce High Temperature Gaskets

/in Uncategorized /by atiadminEven for high temperature gaskets, Gasket Engineering is always looking for the most profitable part production for its clients and always considers multiple processes in order to recommend the best methodology that will help the client find the most economical process possible. Albert Diederiks, Inside Sales Account Manager explains, “It’s our responsibility to give our clients options so that they can choose the best way to go forward.”

A Heavy Duty Vehicle manufacturer recently came to the experts at Gasket Engineering recently with an interesting challenge. They needed high temperature gaskets for the right and left sides for the exhaust of a Class C truck. This was a new product for them, so they reached out to us to help engineer the product in the best way possible. They were looking for the most profitable part production for their new part. Because the gasket would be used in an extremely high heat situation, they needed something that would provide appropriate buffering capabilities while still maintaining its ability to hold up to the high heat of the engine.

MetalTech makes fibrous gasket facing materials that are bonded to a starburst- or rectangular-style perforated steel core or have special coating like Teflon™ or other materials. These provide excellent sealability, good load retention, crush resistance, lateral stability, more bonding points or more conformable materials that are excellent for use as exhaust gaskets, manifold gaskets, head gaskets, heat shields or other high temperature gaskets that are subject to frequent thermal cycling. These are highly engineered materials that can be difficult to cut.

Gasket Engineering provided them with one option to diecut the material to create the high temperature gaskets. The engineers determined that method would produce a very clean-cut, but they also conceded that the yield would be lower and that there would be a lot of waste created using a traditional die cutting process. As they are always looking for profitable part production, that led our experts to recommend a flash cut that allowed for much closer nesting (and therefore less waste) for this expensive material.

Samples were sent to ensure that the edge was clean enough for the process required, the samples passed testing and the client was very happy with this money saving solution for their high temperature gaskets.

Do you need more profitable part production for your next project? Give us a call at 813-363-8333.

Crafting Intricate Parts: How Rotary Cutting is Like Seven Layer Dip

/in Uncategorized /by atiadminIntricate Parts

Although the finished product will not be edible, rotary cutting can stack a variety of “ingredients” and make them as palatable to a manufacturer as the best multi-layer dip is to a party guest.

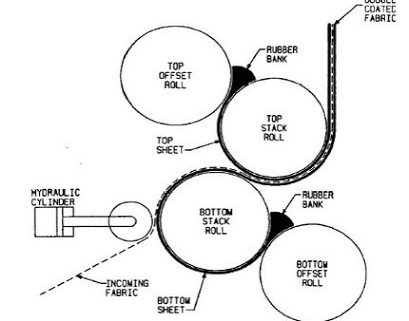

Typically used for high-speed, high volume projects that require anywhere from two to seven substrates to be joined to form a part, rotary cutting has been part of Gasket Engineering’s offerings since the 1990’s when the company made nearly 60 percent of the US-based intricate parts needed by Motorola.

What’s so great about rotary cutting?

Gasket Engineering’s advanced rotary cutting capabilities have the ability to process multiple substrates in one harmonious pass. This type of process makes a nice, clean homogenous part out of multiple materials.

But it’s much more complicated and intricate than just laminating seven layers together. You can also remove and introduce liners, use different adhesives on different sides of the materials and stack different materials on top of each other.

Clients bring us incredibly complicated and intricate parts that need to be made–ones with voids and adhesives and liners and precision requirements from every industry imaginable. That’s probably why we ask so many questions–because we want to get it right! We know that there are so many elements that need to be considered in properly making an effective part. Our expertise in designing the proper processes is just as important as our knowledge of materials and production methodologies.

Intricate Processes

Sequencing is important.

Our knowledge of the right process design is only secondarily critical to the finished product itself. For example, it would not be uncommon for a customer to request to have a conductive material sandwiched between two insulatory materials and then have another adhesive that is put on a liner. That material could have multiple cuts so that some of the conductive material is exposed while some of it is covered.

For these types of intricate parts, those layers have to be processed at different times and in different ways in order to be properly laminated or delaminated and have the appropriate cut patterns and adhesives laid down. That process needs to pull off scrap at the right time and make multiple cuts in multiple materials.

That’s how we make the intricate parts that are customers bring to us. Our engineer has to be my knowledgeable about the materials themselves and how best to convert them, as well as how to properly process them through one of our machines. It has to be sequenced properly so that it doesn’t negatively impact other layers or aspects of the part production. That’s why we say that the sequence is as important as the material placement.

Our experts also need to be familiar with which machines should be used for different jobs. We run our rotary cutting projects through one of two different types of machines. Our Delta presses are software driven so each station can run at independence speeds, while the Allied presses all run at the same speed. Depending on the types of parts being made and the particular requirements of those intricate parts, our engineers will recommend the right machine for the job.

No matter which machine you use, we have optic registration on all machines for maximum precision.

Have you got ayn intricate parts or tricky problems that you’d like help with? Feel free to give one of our engineers a call at 813-363-8333. If you’d like to read more about our rotary cutting capabilities, download our free ebook about The 10 Most Important Considerations for Rotary Cutting here

Director of Sales Boyd Comfort is a guest on this week’s edition of Composites Weekly, a podcast that brings the latest news and information in the world of composites to listeners, discussing new technologies & emerging markets within carbon fiber, 3-D printing and FRP (fiberglass reinforced plastic). This particular episode highlights how Gasket Engineering is helping customers eliminate waste, save on material shipping costs, shrink downtime and provide kitted materials exactly suited to customers’ needs. You can listen to the podcast here.

In this interview, Boyd talks about the company’s history of making gaskets via traditional die cutting and how they expanded to rotary die cutting and dieless cutting, building expertise all along the way. He talks about how we supply custom gaskets to a wide variety of industries, including aerospace, alternative energy and marine applications, converting and binding virtually any raw material into the exact shape, dimensions, and thickness required for your manufacturing needs.

Less Work, More Profit: Converting Expertise That Converts to the Bottom Line

/in Uncategorized /by atiadmin“Doing it this way requires less work and provides us with more profit, and who wouldn’t want that?” That’s the question Mark Kirk asks to explain why they work with Gasket Engineering. Mark is a Wind Energy Sales Manager at Composite One, a leading distributor of a wide range of fiberglass and other composite materials and one of several Gasket Engineering suppliers who have also discovered the many benefits of being a customer s well.

Obviously, for wind blades, bird strike damage can be a real problem. The blades are precisely engineered to harness the power of the wind. They are designed to be lightweight but powerful, efficient and durable. Damage from a bird strike can negatively impact the performance of a wind blade. In addition to the labor required, costs to repair these massive blades include costs to rent a crane for the day to fix the blade and several thousand dollars for patching materials.

Prior to working with Gasket Engineering, Composite One was shipping the materials in their standard 200-lb rolls to the repair sites; the cost to ship the material was often much more than the cost of the material needed to repair the job! Typically, the customer only needs a small section to repair the damage. Mark explained, “We are a distributor, not a manufacturer, so we couldn’t efficiently do what needed to be done. Gasket Engineering has refined the process so well and figured out the secret of kitting and pattern cutting so that there is absolutely no waste. No shop has less scrap; they are pretty phenomenal.”

The experts at Gasket Engineering were able to propose a way to cut and kit the proper materials in a most cost-efficient way. In addition, their response time was lightning quick, which translates to cost savings in both material and shipping costs. By offering real-time turnaround and using their CNC cutting table and patented nesting software, they are able to nest multiple geometries out of a like material in the most efficient way possible and deliver it quickly just the way the customer needs it to get back up and running. This eliminates waste and lowers overall process costs and downtime.

By teaming up with Gasket Engineering, Composite One is now able to offer precision-cut, kitted composite materials that are perfectly suited for the job at hand. This not only saves the customer on material shipping costs; it also saves on the time needed to repair (reducing crane rental costs), shrinks downtime, and eliminates waste. Mark explains, “Now, with the help of Gasket Engineering, we are sending the right amount of materials needed, and everyone is happy. They have eliminated the headaches without increasing costs. Less work, more profit. That’s why we work with them.”

Complex Rotary Cutting to Fuse Five Layers Into One

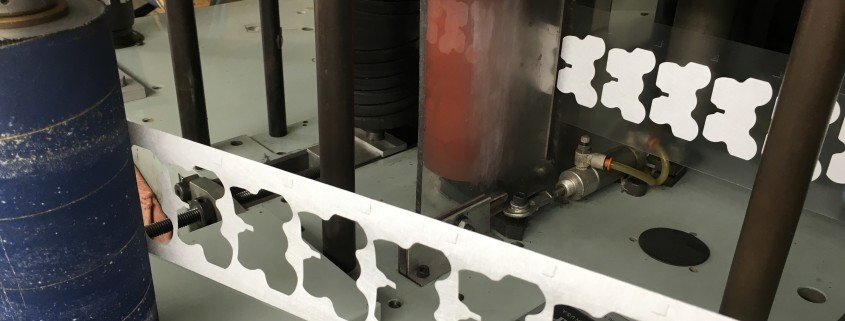

/in Rotary, Uncategorized /by atiadminScientific and medical lab equipment can be very complex so when CLARCOR Industrial Air needed to make a multilayered solution cup vent for one of its clients, the company turned to Gasket Engineering.

CLARCOR is a manufacturer of ePTFE membrane, and it needed to laminate five layers to create a single film for a lab and process industry application. Gasket Engineering’s rotary cutting equipment allowed them to create a sophisticated and intricate product to meet the client’s needs.

Sarah Propp, product development engineer for CLARCOR Industrial Air explains, “The project was fairly complex, requiring us to layer membrane with an aluminum liner. The five-layer film included a support layer, the vent membrane and a pressure sensitive adhesive bonded to aluminum all adhered to an easy to handlerelease liner. While many other converters can’t generally handle layering multiple materials and multiple geometrics into a single product, Gasket Engineering told me ‘No problem’ and went about figuring out how to accomplish what we needed. They are out-of-the-box thinkers who have experience converting materials in non-typical ways.”

With a wide range of machinery available and an innovative approach, Gasket Engineering can convert materials in complex ways that others can’t. If you’re looking for a converter with a unique combination of broad capabilities, creative thinking and a can-do attitude, let the team of experts at Gasket Engineering solve your converting challenges. Give us a call at 816.363.8333 or send a note to gecsales@gasketeng.com

Converter in Kansas City Updates Its Brand Presence

/in News, Uncategorized /by atiadminYou may have noticed that we have a new logo that we launched in the last six months, and we thought we’d tell you a little bit more about that.

You see, we have been looking for a way to honor our past AND express our innovative, future-oriented culture at the same time. It’s important to us to keep abreast of the latest in materials material innovations and offer the broadest range of processing capabilities possible. We wanted our logo to represent both customer service excellence, expertise in converting and cutting edge technology that we’ve invested in over the past few years.

Gasket Engineering (and its logo) has been around since the 1940s, producing high quality parts for discerning manufacturers in a broad range of industries with its precision die-cutting machines. We’re proud of the strong heritage of customer service and product expertise that our amazing employee teams have always brought to our customers that have made us the premiere converter in Kansas City. We have stayed at the top of our game by investing in new technologies, new capabilities and expanding our facilities over time. Customers in new industries have experienced our over-the-top attention to customer service even as we have added laser cutting, expanded rotary cutting processes and dieless cutting machines to our capabilities.

So how could we honor our heritage and better reflect the forward thinking and innovative attitude we also embody? By updating our logo and brand presentation, our clients will get a better sense of what they’ll get when they work with Gasket Engineering.

The new color palette should feel contemporary and fresh and the sleek design itself feels like it was just cut from one of our many material offerings. We hope you like it, but more importantly, we hope your experiences live up to our high standards.

Latest News

Gasket Engineering is ISO 9001:2015 Certified!October 28, 2017 - 4:14 am

Gasket Engineering is ISO 9001:2015 Certified!October 28, 2017 - 4:14 am We’re in the press (again)!May 25, 2017 - 6:41 pm

We’re in the press (again)!May 25, 2017 - 6:41 pm Got Thin Wall Widths? Laser Cutting To The Rescue!May 11, 2017 - 7:26 pm

Got Thin Wall Widths? Laser Cutting To The Rescue!May 11, 2017 - 7:26 pm Engineered Coated Fabric Or Diaphragm MaterialApril 13, 2017 - 11:14 pm

Engineered Coated Fabric Or Diaphragm MaterialApril 13, 2017 - 11:14 pm Innovation and the Founding of the Gasket Fabricators AssociationMarch 27, 2017 - 7:27 am

Innovation and the Founding of the Gasket Fabricators AssociationMarch 27, 2017 - 7:27 am

Phone: 816.363.8333

Fax: 816.363.3558

Email: GECsales@gasketeng.com

4500 East 75th Terrace

Kansas City, MO 64132